Orchestration des

installations électriques

TAO EMS (Energy Management System) en 2 mots :

Optimisation & Sécurité

TAO EMS est un système unique pour le pilotage et la protection des installations électriques équipées de batteries au lithium.

Véritable chef d’orchestre, le TAO EMS coordonne le fonctionnement des équipements de votre installation afin d’augmenter votre autonomie énergétique et de prolonger la longévité de vos batteries.

Simple à installer et à paramétrer, le TAO EMS intègre des normes de sécurité élevées vous permettant de conserver à tout moment une parfaite connaissance de l’état de votre installation.

Initialement développé pour le domaine maritime, le TAO EMS s’adapte parfaitement aux installations dans des véhicules terrestres habitables (van, camping-car, …) ainsi que dans l’habitation.

Et en prime, le TAO EMS est un produit Made in France !

Un véritable chef d'orchestre

Supervise - Coordonne - Protège

TAO EMS

TAO EMS (Energy Management System), une solution innovante unique pour l’optimisation des installations électriques sur batteries au lithium.

La maîtrise de votre installation

Prenez le large en toute sérénité

Contrôle

Une parfaite connaissance de l'état de votre installation et une maitrise de son fonctionnement.

Sécurité

Soyez averti en cas d'anomalie et paramétrez vos alertes personnalisées.

Longévité

Conservez vos équipements dans leur plage de fonctionnement optimale.

Autonomie

Une gestion de la charge et des consommations pour maximiser l'autonomie énergétique.

Optimise et sécurise

Solution

TAO EMS – Gardez le contrôle de votre installation

Fonctionnalités du TAO EMS

Surveille et protège les batteries pour les conserver dans un cadre de fonctionnement sûr et personnalisable.

Un équilibrage rapide même sur des batteries de grande taille grâce à sa capacité unique d’équilibrer avec un courant de 4A.

Le seul équipement réalisant un pilotage globale de l’ensemble des chargeurs pour une parfaite maîtrise de la charge des batteries au lithium.

Un ensemble de capteurs et d’algorithmes pour la mesure et le calcul des indicateurs clés nécessaires au pilotage de l’installation.

Une solution de simulation de pannes pour contrôler la bonne réponse du système en cas d’anomalie.

Définition personnalisable d’un ensemble d’alarmes et d’actions automatisées sur la base de critères à observer et de seuils d’activation.

Historise les données de fonctionnement de l’installation pour une analyse des évolutions long terme et un diagnostic des anomalies.

Restitution d’alertes déportées, paramétrage et contrôle de l’installation depuis un smartphone, une tablette ou un ordinateur.

Intègre nativement un ensemble de standards et protocoles (SAE J1939, NMEA2000, RV-c, …) pour communiquer avec de nombreux équipements et permet la création de messages CAN personnalisés.

Les apports du produit

Double la longévité des batteries

Augmente la longévité des batteries en les conservant dans des conditions de fonctionnement optimales.

Accroît l'autonomie énergétiques

Supervise les cycles de charge et de consommation afin d'optimiser l'autonomie énergétique des utilisateurs tout en s'adaptant à leurs besoins en électricité.

Le système

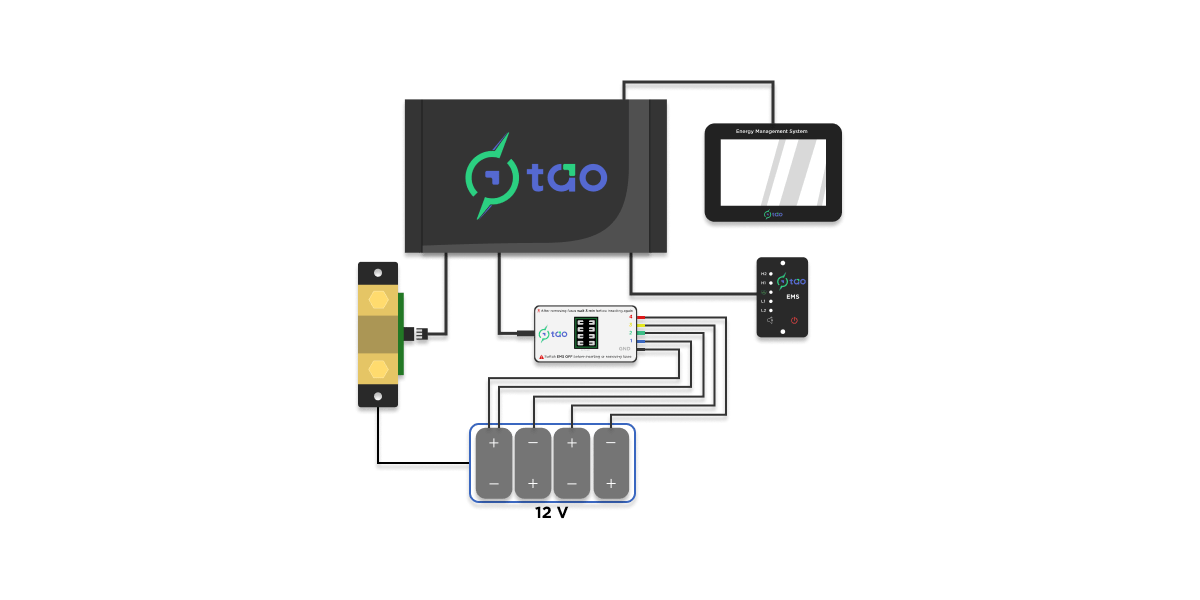

- Un boitier principal pour la supervision du premier pack 12V.

- Connexion aux cellules protégée par des fusibles externes.

- Moniteur tactile pour la supervision et le paramétrage du système.

- Panneau LED pour la restitution d'alertes / alarmes déportées.

- Résistance shunt pour connaitre le courant de charge ou de consommation.

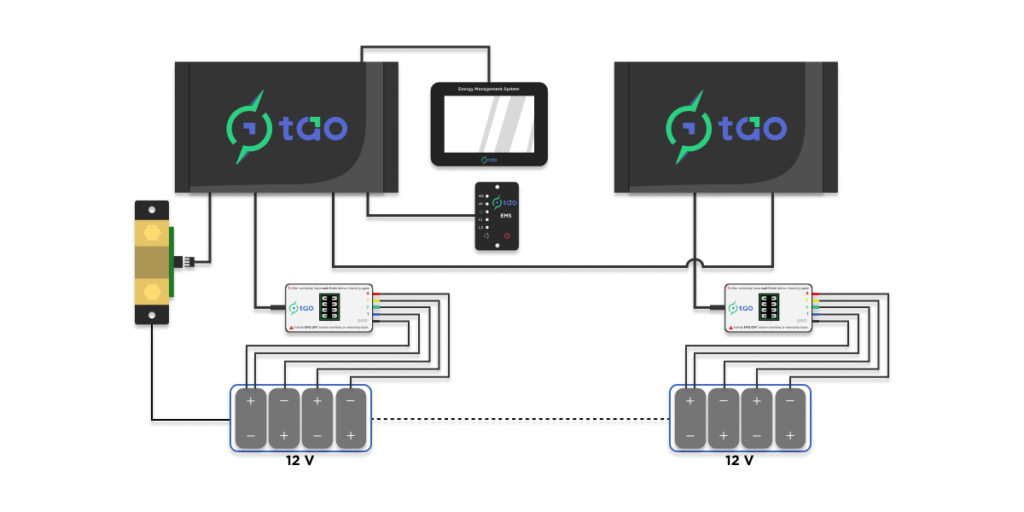

- Ajout d'un boitier extension pour la supervision de 12V supplémentaires.

- La connexion aux cellules reste protégée par des fusibles externes.

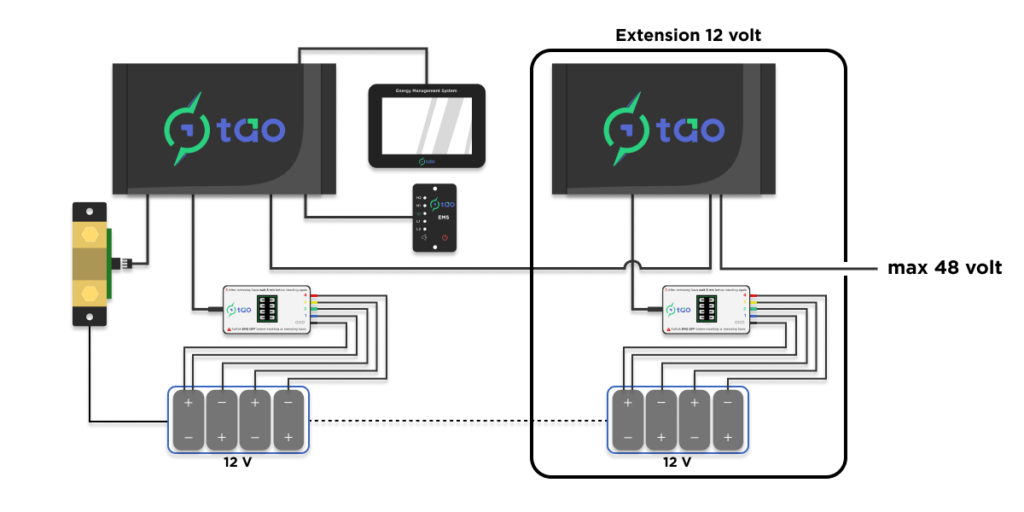

- Jusqu'à trois extensions en série pour superviser des batteries de 48V.

- Supervision, protection et équilibrage à l'échelle du pack batteries complet.

Le système

Installation 12V

- Un boitier principal pour la supervision du premier pack 12V.

- Connexion aux cellules protégée par des fusibles externes.

- Moniteur tactile pour la supervision et le paramétrage du système.

- Panneau LED pour la restitution d’alertes / alarmes déportées.

- Résistance shunt pour connaitre le courant de charge ou de consommation.

Installation 24V

- Ajout d’une extension pour l supervision de 12V supplémentaires.

- La connexion aux cellules reste protégée par des fusibles externes.

Installation 48V

- Jusqu’à trois extensions en série pour superviser des batteries de 48V.

- Un équilibrage à l’échelle du pack batteries complet.

Domaines d'Application

DE LOISIRS

DOMAINE MARITIME

Conçu par un marin expérimenté, le TAO EMS répond parfaitement aux exigences du domaine de la navigation.

VÉHICULES DE LOISIRS

Conçu pour tout type d’installation autonome, le TAO EMS s’installe simplement sur les véhicules de loisir.

Restons en contact

N’hésitez pas à nos contacter si vous avez des questions au sujet de TAO Performance ou de nos produits. Nous reviendrons vers vous au plus vite.

*Champs obligatoires

Ils nous soutiennent